The core business of Artema Pack is the creation of automated end-of-line packaging systems.

We offer a comprehensive range of solutions, from the supply and integration of case packing machines to the overall design and building of the plant, including belt conveyor and palletization systems.

Our broad expertise gives us a broad understanding of the best packaging solutions available and allows us to offer a full range of consultancy services, which extends to primary packaging thanks to the recent acquisition by Galdi.

In other words, Artema Pack is your one-stop reference point for all your packaging needs, starting from our qualified and attentive support.

Advice on secondary packaging selection

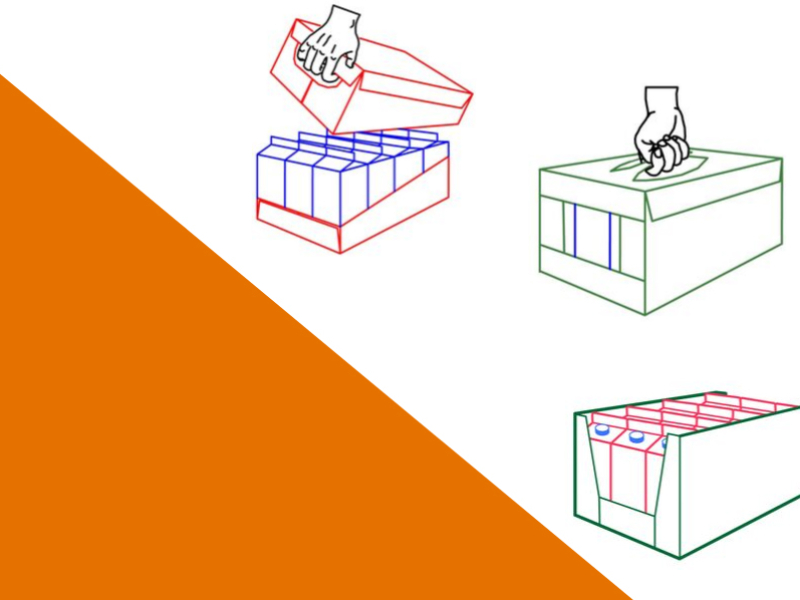

There are several types of secondary packaging carton in the market, with varying quality levels, costs, internal structure, thickness, and so on.

At Artema Pack, our role is not to recommend the most visually appealing, robust or convenient box, but the most suitable one, that is, the one that considers all our clients’ needs as well as several criteria:

Product weight and density

When choosing the right end-of-line packaging solution, the product weight and density cannot be overlooked.

For low-density products such as dry fruits or puffed rice, it may be possible to use a thinner (and cheaper) type of carton, while also considering any palletization requirements and the carton’s carrying capacity.

For heavier products, the carton requires a stronger internal structure and thickness. To safely convey and distribute the products, attention must be also paid to gluing and to the correct position, quantity and extension of the glue points.

Die-cut cardboard design

Some of our clients already know what type of packaging they would like to use for their products, while others need our support in planning their package, starting from a sketch or telling us about their needs.

In these cases, in addition to offering advice, Artema Pack may also directly oversee the design of die-cut cardboard, creating highly customized solutions in terms of visual and technical features.

Let’s take for example the case of a client who wants its product to be visible from the outside, following the recommendations by his distributor.

While a windowed box may be a solution, the design shall also be visually appealing – matching the window with the product name or type (e.g. red wine) – as well as technically performing – ensuring that the box has enough carrying capacity.

Here’s where Artema Pack expertise comes in to recommend and plan the most suitable solution, i.e. the one that fulfils all requirements and guarantees our client satisfaction.

Package graphics

The visual effect of the carton depends on many factors, such as budget, brand positioning and the distributor’s requests. Options range from raw cardboard to two-colour printing, to more complex designs for dispenser boxes intended for shelf exposure.

Solutions for premium product include cartons with external layers of glossy paper or sensory effects, equipped with tearable caps, dispensers or bespoke handles.

Primary packaging orienting

Gable Top packaged products may be oriented with the lid in various positions, either side-facing, front-facing or rear-facing.

Some packaging machines only allow rear-facing orientation, which could be detrimental when envisaging new business opportunities. When a distributor asks for secondary packaging for shelf exposure, primary packaging must be front-facing and not all packaging machines allow it to be done at reasonable costs.

Once again, Artema Pack likes to think forward. We strive to get a clear picture of the client’s possible requirements, including future ones. Our goal is to plan our machines in line with our client’s requests, not the other way around.

Transport and distribution

When selecting the right end-of-line packaging solution, the package’s whole journey must be considered, from transport to distribution up to the end client’s home.

That’s why the package must guarantee safety and convenience of transport (as in the case of boxes with handles) and respond to specific marketing needs, such as trays or packages with peculiar shapes or tearable caps.

One example is that of cold chain or frozen products.

Indeed, humidity makes even the thickest carton boxes softer and less resistant. With deep-frozen food, a change in volume may also occur due to the rise in temperature which happens during the homeward journey.

In this case too, we at Artema Pack can help our clients choose the right box and carton while protecting the client’s image. Indeed, a box that breaks down causing the product to spill isn’t the best publicity.

Layout planning

Planning the layout of an efficient plant is a complex yet fascinating process, based on an extensive array of factors:

- area configuration

- operating machines

- type of packaged products

- production capacity

- number of staff

- passageways

- minimum regulatory spaces

- access spaces for maintenance

- belt conveyor systems

- etc.

That’s why counting on experienced planners makes all the difference in terms of production and logistics.

Thanks to our long-standing experience in planning and building automation systems, Artema Pack offers significant added value, turning complexity into simplicity and maximum efficiency.

Belt conveyor system

A highly functional belt conveyor system is the perfect companion of production processes, making them simpler and faster.

To obtain results, the planning phase must consider several factors:

- Plant layout: the conveyor system must perfectly integrate with the production area, taking into consideration for example any inclines or elevator systems (either linear or rotating ones), all with one goal: to optimize all processes, from primary packaging release to palletization.

- Primary packaging machines: the belt system must match the fillers’ speed and guarantee constant performance, in line with the pace of production and possible downtimes.

- System performance: the belts motorization must reflect the required power (as in the case of inclines) and consumption, in view of maximum efficiency.

- Primary packaging orientation: the belt conveyor systems also allow you to adjust the landing position of the packages into the case packer, as in the case of dry food bags, which may be carried horizontally on the belt and then lifted during transport.

In this case too, Artema Pack’s attentive support in the choice of secondary packaging, combined with our careful planning, represents a much sought-after added value for production managers.

Optimized palletization

The palletization of secondary packages must meet both safety rules and cost and time constraints, as well as existing transport regulations.

At Artema Pack, we help our clients define the ideal palletization system (box groupings, boxes with or without caps, interlocking or layered palletization, etc.) according to the requirements, weight and carrying capacity of the end-of-line packaging. All this is done with an eye on return: indeed, a well-designed automated palletization system brings significant savings over time.

Another essential factor in the pre-shipping phase, yet often overlooked, is the marking, labelling and barcode reading system linked to the ERP.

There are two alternatives: pre-printed labels or ink-jet printing on the filled box.

Our technicians will advise you on the most suitable solution according to your processes.

After all, even a little slowdown may result in significant losses over time!